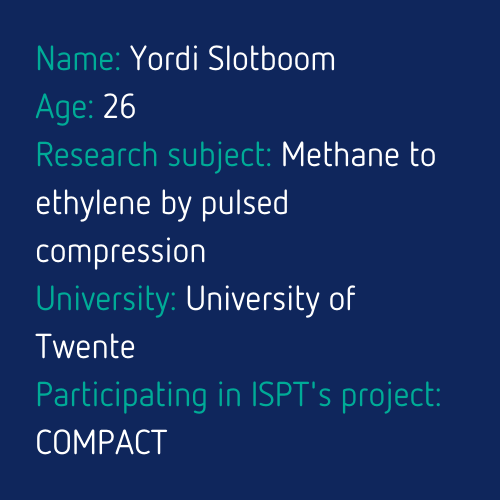

What is the viability of pulsed compression technology for industrial purposes? This is the core of my research for ISPT’s COMPACT project. My name is Yordi Slotboom, I am 26 years old and in the third year of my PhD at the University of Twente. I am carrying out research in the field of chemical engineering, specifically the conversion of methane by pulsed compression which is part of the COMPACT project. Recently my first scientific article was published in the Chemical Engineering Journal.

My research, focusing on methane to ethylene conversion by pulsed compression, is about introducing an alternative technology to convert methane. Methane is of interest because there is a high demand for cleaner carbon sources and fewer carbon-dioxide emissions. The pulsed compression technology enables the use of (bio)methane as a cleaner carbon feedstock. Pulsed compression is the quick compression of a gas mixture to a very small volume. This causes the temperature to rise sharply and with the high temperature, methane can be pyrolyzed to ethylene. This research identified a new operating window with high selectivity to useful products, no soot formation and no deactivation over time. Therefore it is interesting for industrial applications.

Convert methane to ethylene with high selectivity

I am still in the middle of my research and so far the main conclusions are well described in my first article. The concept works, we are able to convert methane to ethylene with high selectivity. The reaction is driven by temperature and the product distribution is dependent on parameters like pressure and feed composition. The speed of quenching of this reactor and the addition of hydrogen can fully suppress soot formation, which is key to this research. Currently we are working to further optimize the ethylene yield and we are working on investigating the efficiency of the reactor in a continuous concept.

Background of the researcher

I currently live in Hengelo but I was raised in a small town called Neede, which is very close to Hengelo. From there I moved to Enschede in 2013 to start my bachelor’s degree in Chemical Engineering at the University of Twente. The study and the environment suited me well, so I pursued a Master’s degree in Chemical and Process Engineering, followed by my current PhD. I like the scenery around here, so I love to go for walks and bike rides. I also like to climb and to play the guitar.

My love for exploring the way nature works inspired my academic path. I find great joy in walking down the road of details that are found in science. I realized this during my graduation and so wanted to pursue more of it. We still have so much more to discover and to be able to contribute to that is a great inspiration.

Research project

I heard about the COMPACT project during my Master’s graduation project. While carrying out my Master’s project at the Sustainable Process Technology group, I enquired about possible PhD projects. I really liked the novel reactor concept for pulsed compression, and the challenging methane pyrolysis chemistry that was proposed to perform the research on.

From my Master’s project I learned that I really enjoy experiments in combination with modelling to achieve the highest understanding of the subject. This is exactly what the COMPACT project had to offer and also why I chose to pursue this PhD. The High Pressure Lab at the University of Twente enables one to carry out research and offers the possibility to study experimental setups that are directly relevant to industrial applications. I find it important and enjoy carrying out research on potential real life applications. So finally, the subject and university turned out to be a great match for me.

Extensive network

I enjoy working with the Institute for Sustainable Process Technology (ISPT). I first heard of ISPT before starting my PhD. I got in touch during the kick-off meeting of the project. It was in ISPT’s school building in Amersfoort, which is an interesting and refreshing location. My impression of the organization is that they have an extensive network of industry and universities and that they are able to connect many different parties. I think that this sort of cooperation is a great opportunity for all parties involved.

COMPACT’s future potential

I hope we gain enough insight to determine the potential of the concept once we finish the project. It would be great if this technology would lead to an actual industrial application. There are quite some challenges to overcome, but this technology can deliver great potential! I would really like to be involved in developing this technology further into industry. If that is not a possibility, then I would happily research another subject and help bring it to market.

Acknowledgement

This project is co-funded with subsidy from the Topsector Energy by the Ministry of Economic Affairs and Climate Policy.