The Plasma Conversion project looked at ways to identify and realise a much cleaner industrial-scale alternative to the energy-hungry Haber-Bosch process. It has taken a number of promising first steps, and made important recommendations for future work.

What’s at stake?

Plasma conversion has the potential to be a gamechanger for the chemical industry (and the rest of us) when it comes to producing ammonia. And the game really needs to be changed: activating nitrogen at high temperatures and pressures, in what is known as the Haber-Bosch process, accounts for about 1% of global CO2 emissions. That might not sound like that much, until we realise that it’s equivalent to around 450 million tonnes of CO2—that’s one giant carbon foot, stomping on the planet year in, year out.

A cutting-edge programme

The Energy Saving in Industry programme, which was set up by Top Sector Energy in 2015, seeks to explore and develop innovative technologies that lead to the more efficient and cleaner use of raw and auxiliary materials. It was as part of the programme that the Plasma Conversion project set about examining a number of different ways to come to an environmentally clean alternative to Haber-Bosch—one that relies on electricity instead of fossil fuels, and that generates no direct CO2 emissions as long as the electricity used is green. (That will, of course, require the development of ways to store green energy.)

From drawing board to realisation: a path strewn with challenges

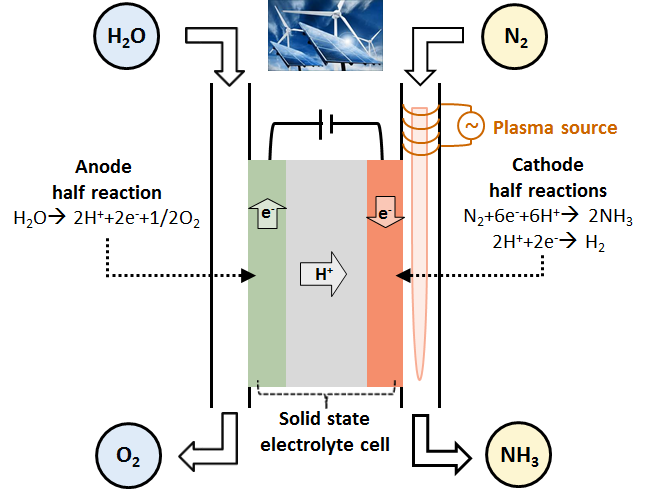

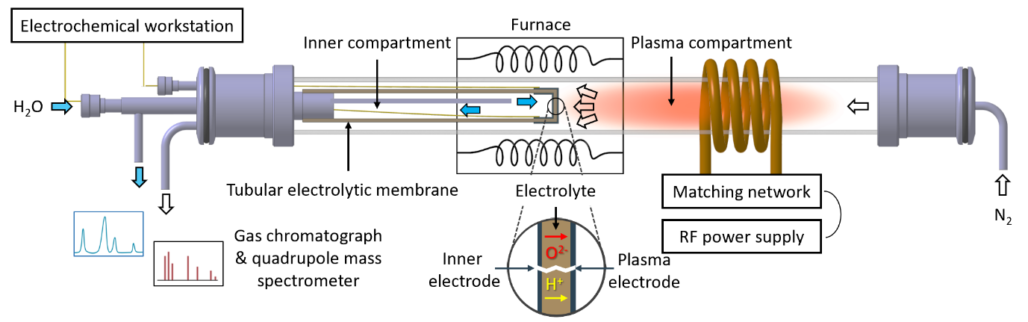

Let’s start with the drawing board: the basic idea, at the highest level, is to combine water splitting with the activation of nitrogen plasma to produce ammonia in a single reactor that relies entirely on electricity. (For “basic idea”, read: “The devil is in the details.” Game changers don’t come easy.) The project investigated various ways to do this. It found that some avenues held real promise, while others would not be viable for a number of reasons. It also came up with a proof of concept and a way of estimating how efficient plasma-assisted electrochemical synthesis of ammonia could be; investigated the use of plasma chemical looping to develop efficient catalysts to synthesise ammonia; and looked at the prospects of plasma-assisted ammonia synthesis.

The presentation of findings, scientific and otherwise

The report the project issued discusses the science involved in these various scenarios. It concluded, among other things, that plasma-assisted NOX synthesis has considerable potential to become a viable alternative to nitrogen fixation, and that it could lead to a significant reduction in capital expenditures if it were implemented on an industrial scale.

The project team presented these and other findings at various national and international conferences and published in journals with a high impact factor. But the report also refers briefly to a number of organisational and other hurdles that any attempt to take the most promising options from the drawing board to full-scale industrial implementation would need to overcome. For instance, to help bridge the gap between fundamental researchers and end users in industry, the report suggests that future work might also involve a technology provider and a work package focused on the design of a pilot plant.

Recommendations for future work

The report wraps up on a positive note, finding that preliminary results are encouraging, even as it recognises that we’re still at a really early stage of the game. Most generally, it finds that plasma-assisted NOX synthesis shows considerable potential, because it is likely to consume much less energy and require significantly lower capital outlays than the Haber-Bosch process + Ostwald process. And it recommends a focus on increasing the production rate and finding ways to reduce how much energy is needed for that synthesis, including by working towards a detailed characterization of plasma flux, striving for a better understanding of the synthesis, optimizing reactor design, and developing efficient catalysts.

Quite a set of challenges—but with so much at stake, the efforts will be worth the candle.

Acknowledgement

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.