The Netherlands has set a goal for full circularity and climate neutrality by 2050. We envision a waste-free economy, that runs as much as possible on sustainable and renewable materials, and in which products and raw materials are either recycled or reused. These goals are laid down in the Climate Act on May 28, 2019. To achieve these goals, our MOOI-projects connect consortia to create complete solutions that contribute to climate goals. Together.

For a circular and carbon-neutral industry, we have to work together. Therefore, the Institute for Sustainable Process Technology (ISPT) in Amersfoort, the Netherlands, initiates and drives joint initiatives through the MOOI-scheme (de MOOI-regeling).

- Our mission-driven innovation policy places the goals of the Climate Agreement at the center of each program

- By doing so, we contribute to the climate targets set by Dutch government

- Which are: 49% less CO2 emissions by 2030 and 95% less by 2050

- Therefore, we connect consortia of cooperating parties to develop innovative solutions in mutual cohesion

Consortia: let’s innovate together

In a consortium, all relevant disciplines and perspectives come together. Entrepreneurs, scientists, civil society organizations and other stakeholders consider the technical and societal factors and opportunities.

Together we work on new, feasible and innovative solutions that can be implemented before 2030 and will lead to full circularity by 2050.

Our granted 2025 MOOI-projects

Advanced Carbohydrates Biorefinery (ACB): From Waste to Value

The Advanced Carbohydrate Biorefinery (ACB) project brings together industry, science and technology to transform cellulose-rich waste streams into polylactic acid (PLA) – a sustainable, biobased plastic with real-world applications. This project converts waste into new building blocks. By turning cellulose into glucose, then lactic acid, and finally PLA, the consortium demonstrates a full-cycle, sustainable process – one that aligns with the Netherlands’ circular economy goals.

Our granted 2024 MOOI-projects

FlexPower: Accelerating industrial electrification for a CO2-neutral future

FlexPower accelerates the transition to a CO₂-neutral industry by developing flexible and efficient electrification solutions. The project enhances understanding among stakeholders in the energy value chain and empowers industries, grid operators, and energy producers to align energy demand with renewable supply. This alignment supports electrification, while maintaining industrial productivity and competitiveness and addressing challenges such as grid congestion, imbalance, and energy price volatility. Through real-world case studies and system-level innovations, FlexPower provides actionable insights to enable sustainable and flexible industrial electrification.

Our granted 2022 MOOI-projects

Renewable Building Blocks from complex mixed and wet waste streams (ReBBloCs)

To match the demand for renewable building blocks by industry, we need to valorise all waste sources, including the so-called complex and mixed waste streams. To convert these challenging waste streams into circular and biobased and platform chemicals, new value chains need to be developed. ReBBloCS will develop these value chains in collaboration with all relevant stakeholders such as industrial end-users, waste-owners, technology providers and knowledge institutes. By valorizing all waste streams, we make the industry more sustainable and stimulate circularity.

Our granted 2021 MOOI-projects

HyScaling: Developing the hydrogen supply chain and position the Dutch high-tech industry

HyScaling develops the hydrogen supply chain and position the Dutch High tech industry to enable the cost effective implementation of up to five GigaWatt electrolyser capacity in the Netherlands by 2030. In addition, it plays a key role in the global roll-out towards 100 GW. The HyScaling project has two high-level key objectives to support rapid development and implementation of technology:

- Make better electrolyser systems – improvement and cost-reduction of technology.

- Make electrolyser systems in a better way – development of manufacturing capacity.

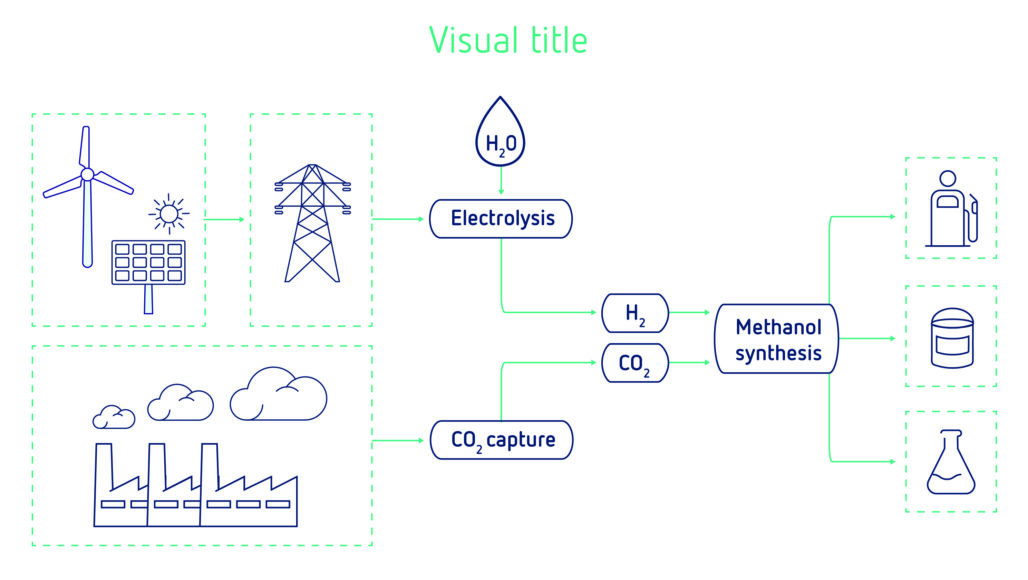

PROVE IT: PROducts of Value from various CO2 sources, Enabled by Integrating Technologies

PROVE IT showcases methanol production from CO2-rich industrial off-gases (technology development) in the context the evolving industrial system (system analysis). It develops robust technology that captures & separates CO2 from various (contaminated) industrial off-gas sources for efficient conversion to methanol using renewable energy. In addition, it demonstrates feasibility of the technology within an industrial system-in-transition context.

InReP: An Integrated approach towards Recycling of Plastics

InRep aims to develop an integrated approach of the most sustainable and economic viable choices of plastic packaging based on circular objectives which are demand driven by the industry. By implementing the main results of InReP, namely the development of technologies in sorting, mechanical and chemical recycling, in 2030 the availability of high quality recyclates will be significantly increased for the two dominating polymers; polyolefins (PE/PP) and PET.

The Heat is On: Towards a CO2 free industrial processing system

The Heat is On aims to assist the industry in complying with the climate objectives by improving the sustainability of their heat driven industrial processes. In addition, the project intends to realize solutions for optimal process efficiency in drying and dewatering as well as in systems for heat recovery for the participating industrial partners. Effective integrated solutions are aimed for optimal combining in process efficiency solutions with heat reuse and a total system perspective on electricity usage.

Interested in regular updates on our MOOI-projects? Subscribe to our newsletter or join our LinkedIn-community.