This report (written by Haskoning, as part of the H2-Safety2 project) aims to map the needs relevant to safety standardisation during the multiple project phases of the design and operation of green hydrogen production facilities and the related permitting process.

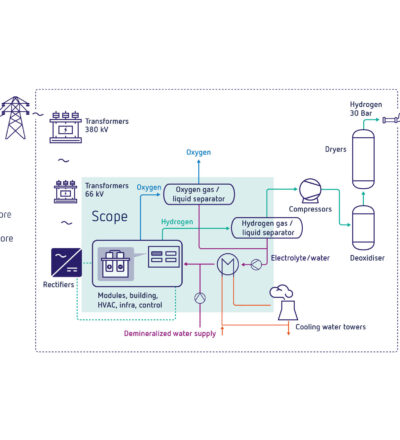

The scope is green hydrogen production using Alkaline Water Electrolyser (AWE) and Proton Exchange Membrane (PEM) Electrolysis with multiple stacks and the accompanying processing units, gas/liquid separators and knock out drums. The target audience for this report includes companies involved in the design, operation, and technology development of green hydrogen production facilities, representatives of authorities involved in the permitting process for green hydrogen production facilities, inspection bodies and committees as well as knowledge groups to whom safe green hydrogen production is of relevance. This also includes organisations involved in aligning best practices and creating guidelines and/or standards.

The needs analysis was based on:

- A literature review to identify the existing norms and standards. These were evaluated regarding their applicability to hydrogen in general, to water electrolysis and to the effects of intermittent green power supply.

- The report ‘Risk Assessment Approach and Knowledge Development’ (ISPT, 2025) was used as primary input to identify the needs regarding process safety and risk assessment.

- Contact with the representatives of permit issuing authorities in the Netherlands and input from the project advisory board and experiences of the project partners to gain insight into the needs for the permitting process.

Download your free copy

Our publications are free to access. Simply provide your first name and email address to download.