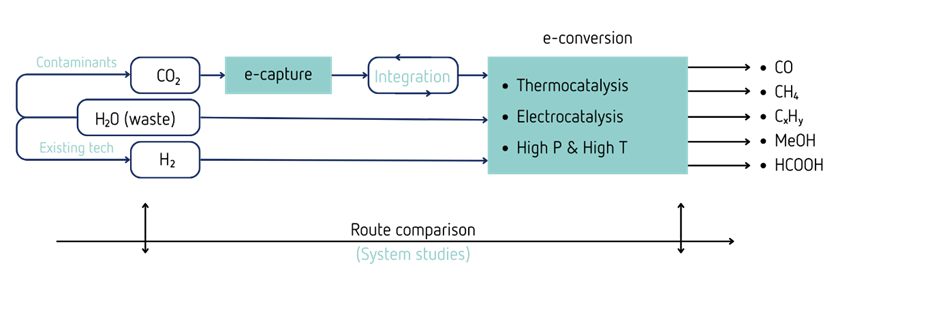

By 2050, it is projected that approximately 100 TWh of industrial energy demands will be electrified, resulting in a significant decrease in CO2 emissions. The SUNSOLr project focuses on developing new technologies for the direct electrification of chemical conversions of CO2 and H2O/H2, aiming to produce CO, CH4, olefins, and methanol.

In short:

- The SUNSOLr project is advancing direct electrification technologies for chemical conversions of CO2 and H2O/H2 to produce valuable chemicals like CO, CH4, olefins, and methanol.

- The project explores both electrocatalysis of pre-captured CO2 and the integrated capture and conversion of CO2, contributing to significant CO2 emission reductions.

- It aims to accelerate the energy transition by providing innovative pathways for sustainable chemical production.

The role of SUNSOLr in the energy transition

The SUNSOLr project is vital in driving the energy transition within the chemical industry by addressing a core challenge: the direct electrification of chemical processes. As the industry moves towards carbon-neutral operations, electrification provides a pathway to reduce reliance on fossil fuels and cut CO2 emissions. SUNSOLr directly supports this goal by focusing on CO2 and water electrochemical conversion to valuable chemicals, aligning with national and global climate objectives. The outcomes of this project will offer the industry new tools and insights to achieve large-scale, sustainable production while contributing to the Dutch climate agreement’s targets for 2030 and beyond.

Direct electrification of chemical conversions

The SUNSOLr project is dedicated to developing technologies for the direct electrification of chemical conversions, focusing on CO2 and H2O/H2 to produce chemicals like CO, CH4, olefins, and methanol. To achieve this, the project explores two main approaches:

- Electrocatalysis of pre-captured CO2.

- Integrated CO2 capture and conversion.

The project’s goals include developing novel technologies for direct electrification and exploring these approaches to ensure effective, sustainable conversion processes.

Critical elements of the electrification process

The SUNSOLr project is organized into four key work packages, each addressing a critical element of the electrification process:

- Electrochemical CO2 Reduction: The project explores the use of supercritical CO2 as a medium for producing chemicals such as formic acid (HCOOH), ethylene (H2C=CH2), and methane (CH4). By operating in a liquid phase like supercritical CO2, the reaction becomes more efficient and productive than traditional gas-phase methods.

- Single-Step Conversion to Methanol: SUNSOLr investigates the single-step electrochemical conversion of CO2 to methanol using proton-conducting ceramic cells. This novel method allows for efficient methanol production, which can be directly integrated into existing industrial processes.

- Electrification of Integrated DAC: Direct Air Capture (DAC) technologies, combined with electrochemical conversion, offer significant potential for sustainable chemical production. The project focuses on capturing CO2 from the air and converting it into light hydrocarbons, such as methane, through electrified processes, eliminating the reliance on fossil fuels for sorbent regeneration.

- Techno-Economic Optimization: SUNSOLr emphasizes the importance of economic feasibility by benchmarking and optimizing different synthesis routes for the production of platform molecules. This work package ensures that the technologies developed are not only environmentally sustainable but also commercially viable for large-scale industrial applications.

Expected results

By the end of the project, SUNSOLr will deliver:

- A verified scientific basis for the investigated electrification processes.

- A comparative analysis and ranking of the conversion routes, along with suggestions for improvement and integration.

- Transfer of process design and evaluation data to industrial partners for further development.

- Preparation of five R&D experts for careers in this emerging field of sustainable chemical conversions.

A long-term vision for sustainable process technology

SUNSOLr is part of ISPT’s Long Term Program (LTP), an ambitious initiative aimed at transforming the process industry by 2050. The LTP focuses on developing groundbreaking technologies that don’t yet exist, envisioning a future where entire value chains—from raw materials to end products—are radically redefined. Through close collaboration with scientists and industry players, the LTP is crafting strategies to implement these technologies effectively and ensure a fully sustainable process industry.

You might also be interested in

Acknowledgement & partners

This project is co-funded with subsidy from the Topsector Energy by the Ministry of Economic Affairs and Climate Policy.