A significant amount of the total energy consumption and emissions are related to food processing. In the PRoFo project, various partners, each representing a different part of the food chain, aimed to achieve a 50% energy reduction. They persued this goal by developing novel process routes in food processing.

In short:

- The food industry is one of the major energy users (95 PJ/yr)

- The Novel Process Routes project demonstrated with a revolutionary new approach that lowering energy consumption for processing of food ingredients by 50% is possible

- Further research will be done in the follow-up project EPRoTrans – Energy reduction technologies enabling PRotein Transition

Reduction of energy use

Industrial partners of our Mild Fractionation Program that participated in the Novel Process routes project are active in different parts of the supply chain. For example, Cosun and FrieslandCampina produce ingredients and consumer products from raw materials (crops, milk). Unilever and FrieslandCampina want to use enriched fractions from these raw materials as a new basis of functional ingredients in their food products. Furthermore, DSM-Firmenich produces enzymes and looks for opportunities to valorize side streams. Finally, Pentair provides membrane technology solutions for food and beverages and water applications.

The drivers for all the industrial partners are sustainability in terms of reduction of energy consumption per kg food product and total use of raw materials.

New Process Routes from crops and dairy materials

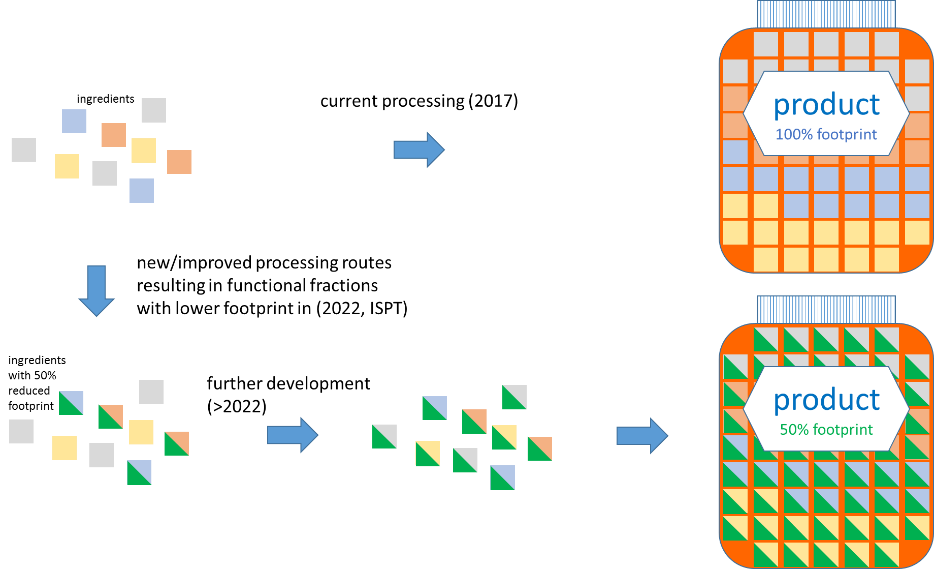

The main goal of the project was to develop and demonstrate novel processing routes or new/improved separation technologies for mildly processed fractions from crop and dairy materials. This would yield functional food ingredients while cutting energy and carbon footprint by 50%. In addition, the water footprint is expected to reduce substantially. This reduction stems from substituting current ingredients with functional fractions produced using novel technologies and routes, as depicted above. Ultimately, this groundbreaking approach could result in a 50% decrease in energy consumption during food processing.

Activities

The following activities were foreseen in this project in order to get successful results:

- Investigation of portfolio of enriched fractions from dairy and crops

- Design of processing routes for production of enriched fractions with minimal energy consumption and maximal valorization of total crops/raw materials

- Design of separation technologies needed for novel sustainable processing routes

- Application and control of enriched fraction functionality in process routes

- Demonstration of successful technologies on pilot scale

Ingredient replacement by enriched fractions

The use of a modeling data analysis tool has proven to be of great help in finding real opportunities for ingredient replacement by enriched fractions of agri-food streams with a footprint reduction of over 50% in processing. Initially, the footprint reduction was based on optimizing the usage of conventional isolates and mildly refined fractions, considering their composition. For 13 out of 14 products (ranging from coffee creamer to vegan whipped cream), the Global Warming Potential (GWP) dropped by approximately 50%. For example, for plant-based meat replacers or spreads, the GWP went down by 70%. However, the techno-functionality of foodstuff is of importance. For example, the rheological properties of pea protein fractions are unraveled (see next paragraph).

Matching functional properties instead of compositions to establish a drop in the Global Warming Potential (GWP)

To speed up development, Machine Learning models could help in quantifying the techno-functional properties (e.g. gelation, viscosity, emulsion stability, foaming capacity). Matching functional properties rather than compositions significantly expanded the formulation space for all products; the impact of the total product portfolio could be reduced by more than 70% compared to the case in which only isolates are used. In this case, for plant-based meat replacers or spreads, the GWP decreased by 90%. Additionally, the water footprint also decreased by 90%.

This work demonstrated that replacing conventional protein isolates with mildly refined fractions could reduce the GWP and, consequently, energy consumption. However, redesign based on functionality must be the new approach for product development. Additionally, this implies that mild refinery processes should focus on extracting functionality from the crop. This was already demonstrated in this project (see below) and also serves as input for the follow-up project EPRoTrans – Energy reduction technologies enabling PRotein Transition.

Water-only Fractionation processes – no chemicals with higher yield

Targeted fractionation of plant-based protein sources, such as yellow pea, is essential to explore new opportunities for sustainable ingredient production. The functionality of the derived ingredients highly depends on the processing and resulting fraction composition. In this project, the potential of water-only processing to fractionate pea flower was investigated. Currently, fractionation processes based on the use of chemicals are energy- and water-intensive, partly because the production of these chemicals (i.e. caustic soda, hydrochloric acid and/or acidic acid) requires energy.

The starting point for developing novel fractionation processes was the consideration that food products generally contain many components, which makes it not always necessary to create highly purified ingredient consisting of only one component. Novel ingredients could potentially consist of more than one component. That is why water-only processes were developed. Omitting the use of chemicals was expected to yield less pure protein, but remarkably, it was found that with water-only processes, combined with several centrifugation steps, high purities could be achieved while simultaneously maintaining a high yield. In fact, the yield and purity were in the range, or even higher than what was obtained with fractionation processes using chemicals.

This finding points in the direction that components in pea flower are mostly loosely bound and fall apart when mixed with water. In this way, water-only fractionation of pea flower has similarities with the fractionation of milk, which explains why this finding was used as the starting point for part of the new EPRoTrans project, which started in April 2023.

Further gains in efficiency can be achieved by using less water. Then, multi-component ingredients, comprising, for example, protein and fiber, could be obtained. To fully understand the functional properties and how to use those ingredients in final products, we followed two approaches. One was based on considering the components to not mix at molecular scale. Then, the rheological properties can be described using the water uptake of the phase with a certain component, their rheological behavior, and assuming which phase will form the continuous phase in the final product. This approach resulted in a model that could describe the properties well.

Membranes and models for plant-protein fractionation

Membrane separation technologies are key for the transition to climate neutral food production. For fractionation of proteins open UF or small MF membranes are used. These systems appear to behave differently than non-fractionation systems and the conventional approach for modelling and design fails. This is caused by the relative high flux through the membrane resulting in either a reduced thickness of the concentration polarization layer or the formation of a dynamic layer in front of the membrane determining the selectivity. Both models are described and verified for the permeation of BSA over an open UF and the fractionation of milk proteins from milk, respectively. These models are the basis for plant-protein fractionation in the new EPRoTrans project.

Side streams into healthy snacks and plant-based dairy replacements

Side streams and other unrefined ingredients that were developed and identified in this project were successfully applied in various food product categories, including healthy snacks and plant-based dairy replacements. Sustainable pea and faba protein ingredients were used to provide texture, emulsification and nutritional value in amongst others gluten free protein-rich breads and dairy free protein-rich cream cheeses. A sustainable, unrefined ingredient from the sugar industry provided sweetness and texture in various desserts and bakery products thereby partially or completely replacing the need for highly refined granulated sugar and stabilizers such as gelatine.

Follow-up project

These revolutionary results gave rise for further research. Hence, the new project EPRoTrans – Energy reduction technologies enabling PRotein Transition has been drawn up. Started in April 2023, this new project aims to use these results as a stepping stone. Its goal is to achieve promising energy savings and optimize the use of functional ingredients and side streams.

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.