The industry is grappling with numerous energy-related challenges, particularly the removal of water from raw material streams. Despite the development of innovative dewatering technologies, their concrete benefits in terms of energy savings per kilogram of water extracted, and their impact on sustainability and product quality, remain uncertain. With escalating costs, volatile energy markets, and sustainability concerns, there is a recognized need within the industry for a more practical understanding of techno-economic analyses, especially regarding alternative drying and dewatering systems.

In short

- Emerging dewatering methods and novel drying techniques are promising

- But we need higher solids content prior to spray drying

- We’re delving into innovative technologies to facilitate this shift

- This could contribute to industry’s energy reduction goals of 50-80% in 2030

Pushing towards higher solids content prior to spray drying

Previous projects have yielded significant progress, enhancing our comprehension of the fundamental principles governing drying and measures to curtail energy consumption. An illustrative instance is the comprehensive research conducted by ISPT and industrial partners on the drying behavior of individual droplets. This research has provided valuable insights into the impact of emerging drying and dewatering technologies on overall process efficiency and product characteristics.

Broadly speaking, the upcoming challenge lies in pushing toward higher solids content prior to spray drying and delving into innovative technologies to facilitate this shift. Additionally, emerging dewatering methods such as membrane systems and novel drying techniques like air-free drying exhibit promise in energy reduction. Although these technologies may necessitate further refinement in design before finding practical application, especially in sectors such as the food industry, the urgency surrounding energy conservation is compelling enough to warrant comprehensive evaluations, considering energy reduction potential, resilience, and product implications.

Enhance implementation of mild dewatering technologies

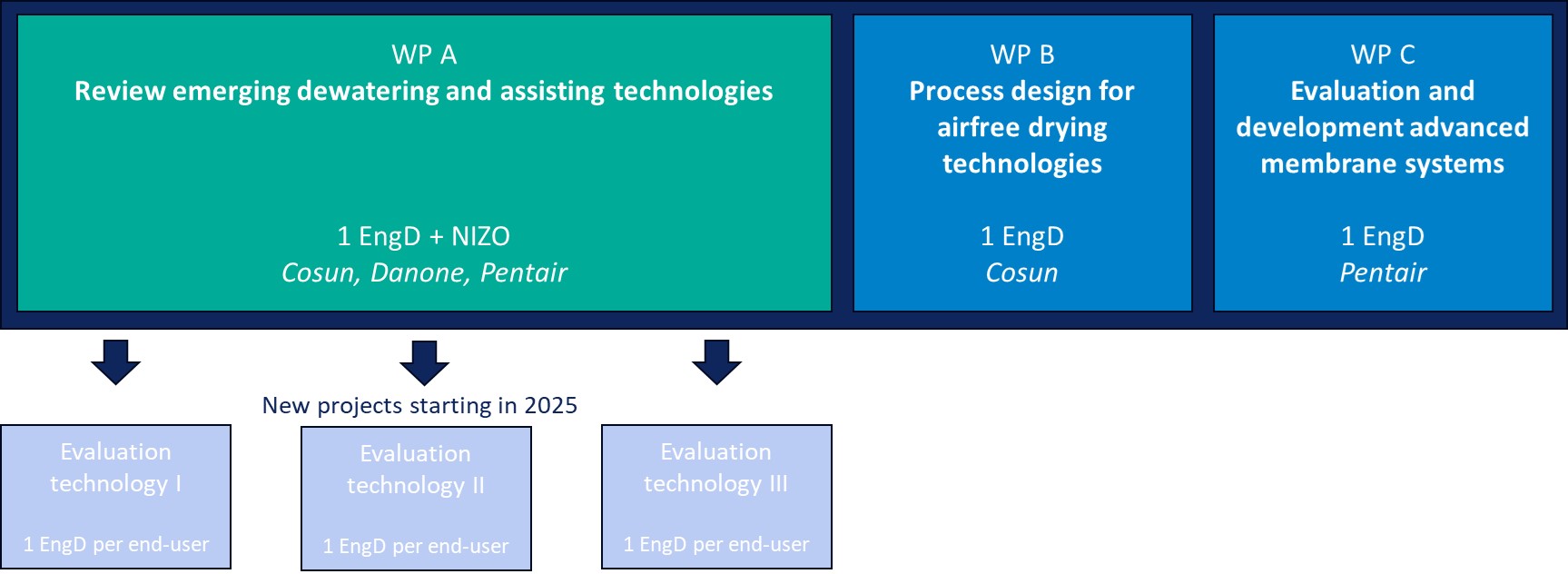

The main objective of this project is to enhance the implementation of mild (energy extensive) dewatering technologies. This will be done by a scientific evaluation of all proven technologies and hybrid combinations thereof for dewatering and drying of streams of interest with regard to specific energy consumption, robustness, TRL and impact on product functionality and sustainability. The evaluation will result in process designs of new or revisited technologies within factories of the industrial partners. The new insights and designs should contribute to industry’s energy reduction goals of 50-80% in 2030.

50-80% energy reduction in dewatering

The following results are foreseen:

- New designs for drying and dewatering with diminished energy aiming at 50-80% energy reduction in the dewatering step while maintaining required product quality.

- List of potential (re)new(ed) technologies that can be applied in the near future.

- Joined effort on energy reduction in the food industry by sharing best practices.

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-Energy with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.