The ECONEXT project brings together partners from across the value chain to unlock the full potential of dry fractionation technology. This approach drastically reduces energy use in plant-based protein production, while enabling a shift to crops grown in the Netherlands and the EU.

In short:

- The goal of the ECONEXT project is to develop science-based strategies to enable dry fractionation to become the dominant processing technology for the production of plant-based protein ingredients

- Producing sustainable, healthy, tasty, and affordable plant-based meat analogues

- Reduce energy use by shifting from wet processing to dry fractionated protein concentrates, from animal to plant-based proteins, and from imported wet-fractionated ingredients (like soy) to locally grown crops (e.g. yellow peas, faba beans)

The challenge

The Netherlands aims to source at least 50% of its proteins from non-animal sources by 2030. But producing plant-based proteins at scale is often more energy-intensive than conventional meat processing. The dominant method — wet fractionation — requires vast amounts of water and energy for drying. There is an alternative technology available, dry fractionation, that offers a significantly lower industrial energy consumption. It even results in protein ingredients with approximately 87% lower GHG emissions. However, it faces functional and sensory hurdles that limit its widespread application, for example in meat analogues.

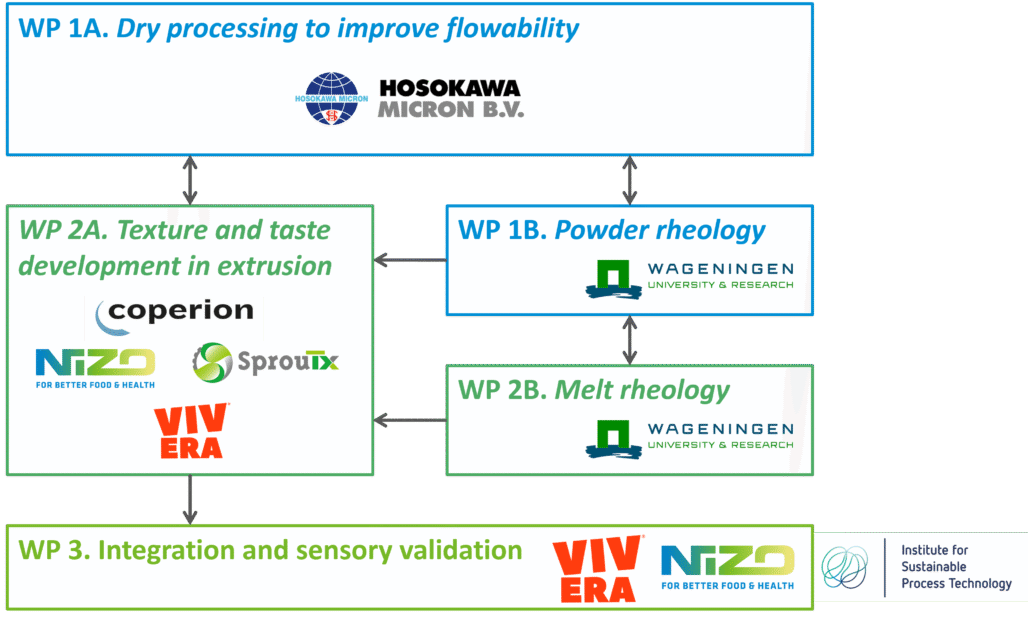

About ECONEXT

ECONEXT is a collaborative innovation project focused on improving the processing performance of dry-fractionated protein ingredients. The aim: to develop science-based strategies that enhance their use in high-moisture extrusion, especially in products like meat analogues. The project targets local crops such as yellow peas and faba beans that can be grown in the Netherlands, instead of imported crops like soy beans. The project addresses issues like powder flowability, viscosity of the protein dispersion, off-flavours, and texture.

Expected results

- Mechanistic insight into why air-classified protein concentrates have poor flowability and strategies to improve flowability (incl. validation in extrusion)

- Insight into the taste challenges of concentrates and strategies to mitigate them

- Strategies to modulate extrudate texture for protein concentrates

- A combined strategy for creating protein concentrates and derived (extruded) products

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.