Upgrading low temperature waste water streams of separation processes with compression resorption heat pumps.

Goal

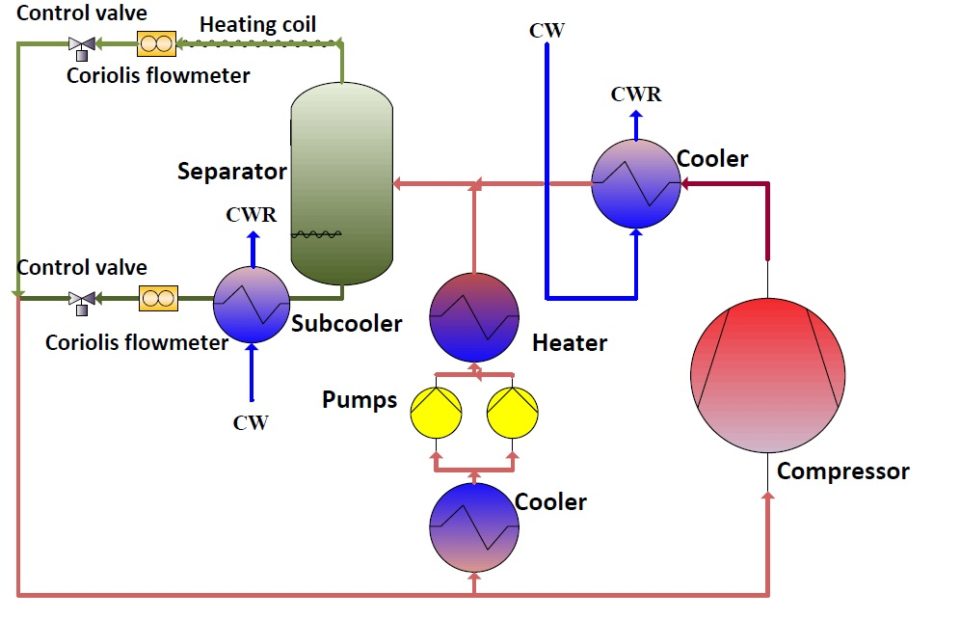

The goal of the COMPRESORP project is to upgrade low temperature waste streams from the process industry (e.g. cooling water from cooling towers) into valuable utility streams making use of compression-resorption heat pumps which operate in the wet regime.

Incentive

Thermal energy (heat) represents a large part of the global energy usage and about 43% of this energy is used for industrial applications. Ultimately, 20-50% of the energy used is lost via waste heat contained in hot exhaust gases and liquid streams. Nevertheless the share of waste heat recovery (upgraded energy) within the total energy used is still negligible.

Compression Resorption heat Pumps (CRHP) can be used to upgrade waste water streams to streams which are applicable for heating and cooling purposes. In this way the rest heat available inthese streams can be re-used in the separation processes. Waste water streams with temperatures in the range 35 to 60°C can be partly cooled down to 5°C and partly heated up to temperatures above the 110°C. These product flows with higher exergy can be used in separation processes which need cooling / heating respectively. Limiting for the commercial introduction of these cycles in practice is the unavailability of compressors which can operate under the operating conditions required by these cycles.

Objective

The focus of this project is on the development of a compressor suitable for the operating conditions of compression resorption cycle and its integration in the cycle.

A compressor prototype suitable for the operating conditions of compression-resorption heat pump cycles for heat recovery will be designed and experimentally tested.

Results

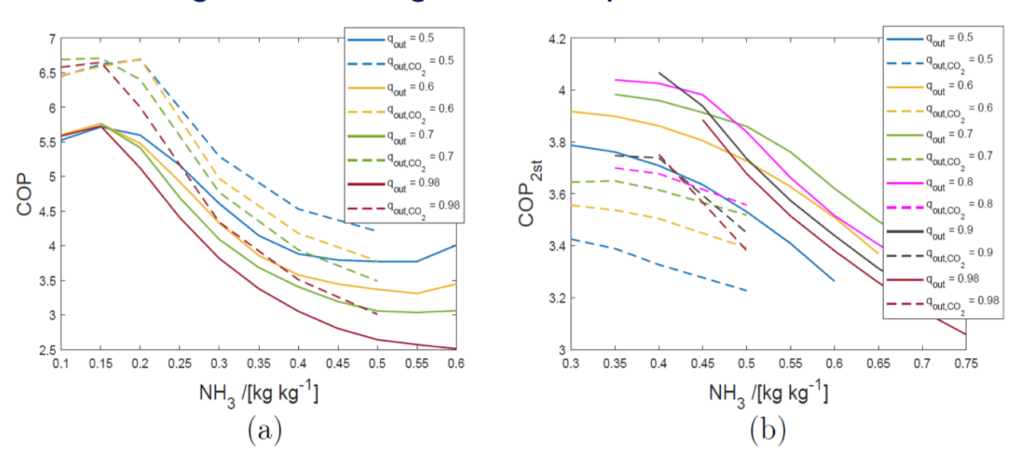

The impact of adding small amounts of CO2 to the working fluid has been investigated. Indicating a ca. 5% improvement in COP.

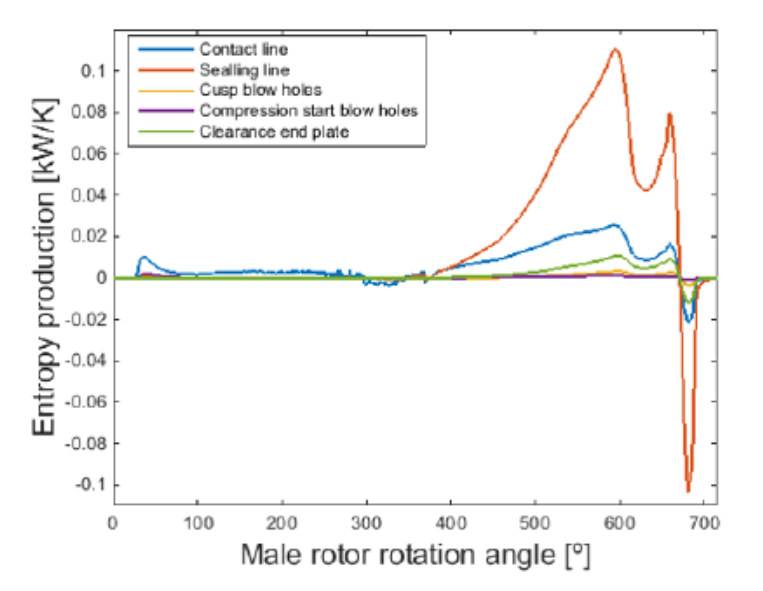

A thermodynamic model has been developed for twin-screw wet compressors which allows localization of major irreversibility losses during the compression process in CRHPs.

An experimental set-up has been constructed at the TU Delft to test the performance of the wet compressor prototype.

A summary of the results can be found in Gudjonsdottir PhD thesis.

You might also be interested in

Articles / Publications

COMPRESORP: Upgrading Waste Heat Streams with Wet Compression (in Dutch)

Entropy production minimization of a CRHP

Absorption of CO2-NH3-H2O mixture in mini-channel heat exchangers

UH-20-10 Comparison of Models of NH3-CO2-H2O Mixture

Wet compression model for entropy production minimization

Enhanced performance of wet compression-resorption heat pumps by using NH3-CO2-H2O as working fluid

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.