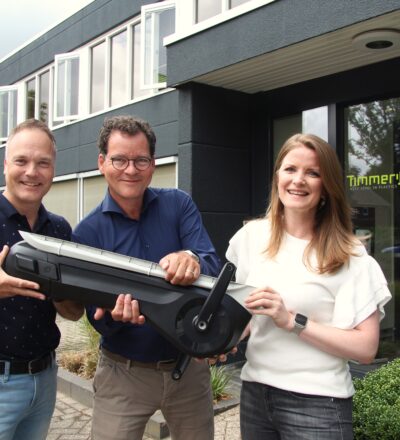

Cindy Bauhuis, Product Design Manager at Timmerije, advocates for a sustainable future through recycling. At Timmerije, the vision is clear: to make all plastics circular, whenever feasible. By championing recycling, Bauhuis envisions a future where we reduce our dependence on virgin plastics, paving the way for a more sustainable tomorrow.

Name: Cindy Bauhuis

Function: Product Design Manager

Organization: Timmerije B.V., Neede

Works with ISPT on: Circular Plastics Initiative ReCYCLE

Why is it important for you personally to contribute to a circular and CO2-neutral economy with your work?

“Our world is undergoing rapid change. Particularly in recent decades, climate has undergone significant transformations, resulting in adverse effects on humans, animals, and the environment. This includes the emergence of more extreme weather conditions, such as higher temperatures, increased wildfires and floods, and heightened dryness.

Besides that, we live in a world where disposability is the norm. People throw things away too easily. This is not only harmful for the environment, but it has also led to a negative image of plastics. There is a lack of recognition for the possibilities and the societal importance of plastics. Instead of using plastics once, then throwing them away and/or burning them, we must shift to a society where plastics are collected and reused. Recycling will give us a more sustainable model for dealing with plastics, where we will be less dependent on virgin plastics. Personally, I find it important to contribute to such a change in the plastic industry.”

There is a lack of recognition for the possibilities and the societal importance of plastics

Cindy Bauhuis – Product Design Manager at Timmerije

How can we accelerate the transition to circular plastics?

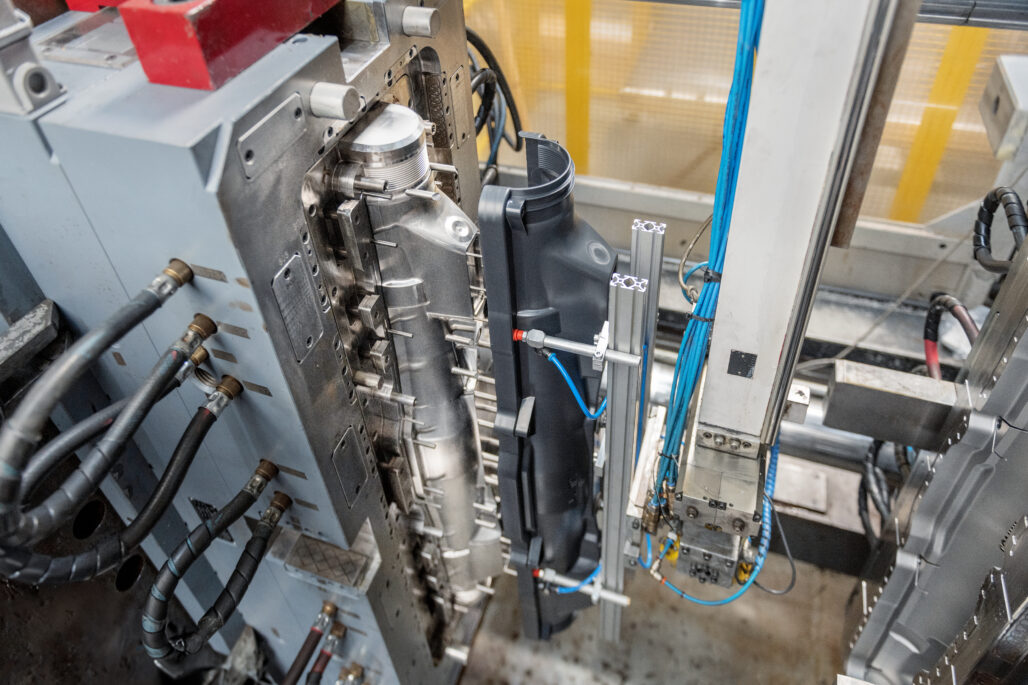

“Within the plastics industry, converters must accelerate the development of showcases utilizing circular raw materials, mirroring the approach taken by Timmerije. This entails reevaluating designs to facilitate recyclability (‘design for circularity’) and enhancing ‘product design for disassembly.’ The latter involves using a single circular raw material for all plastic parts within a product, instead of employing various virgin materials. Furthermore, converters should establish specifications for mechanically recycled materials. Raw material suppliers must expedite the advancement of cost-effective technologies for chemical recycling, which are predominantly in the pilot stage. Recyclers should broaden their range of mechanically recycled materials, particularly targeting technical plastics.

A challenge is that biobased materials are currently limited to packaging and lower-end construction sectors, not applicable to technical plastic parts used by producers like Timmerije. Even with advancements from programs like the Nationaal Groeifonds BBC (Biobased Circular) program, this is not likely to change. Hence, chemical recycling is crucial for the technical plastics industry, offering low carbon/circular alternatives akin to virgin plastics derived from oil.

As a developer and manufacturer of customer-specific technical plastic parts, Timmerije has laid down in its Vision that it wants to make all its products circular, wherever possible and practical. Likewise, CPI wants to move the boundaries to enable a circular plastic economy. For me personally, it is a great opportunity to learn a lot from the knowledge gained within this project, enabling the collaboration with the entire value chain and implementing the acquired knowledge in new and current projects.”

What is your sustainability dream for 2050?

“I envision a future where we use as little virgin plastics as possible, only doing so in cases where there is no alternative available. I think we can achieve this by using different types of plastics and designing the entire value chain completely circular. I also think that, in a sustainable future, there will be more awareness and knowledge about recycling. I also think this knowledge should be available for the customer, making it clearer for them how to correctly use it, collect it, and recycle it.

I think the biggest hurdle we face in becoming more sustainable is that economic prosperity will likely decrease. This leads to different decisions, which continue to be based on money. Circular options must be the most attractive option, also financially, so people will be pushed out of the linear route they are familiar with towards a new circular model.”

Timmerije is involved in the ReCYCLE project, together with Koninlijke Gazelle, Ultrapolymers, Brisk Kumet, PSP Zwolle and ISPT. In ReCYCLE, the focus is on creating durable circular plastic parts for the use of electric bikes, pushing the boundaries of innovation in sustainable engineering thermoplastics.

Acknowledgement

This project is co-funded with subsidy from the Topsector Energy by the Ministry of Economic Affairs and Climate Policy.