Join us in tackling the challenges of industrial electrification and flexibilization! This is your chance to explore opportunities and technologies and expand your network by connecting with industry experts and technology providers. Take up our challenge and make a tangible impact by helping us find the optimal solutions to our virtual industrial heat cases.

The issue

Large-scale electrification of industry is essential to achieve the required CO₂ reductions and decrease the dependency on gas. At ISPT’s Heat Integration Platform, various energy-saving electrification technologies for heat-driven processes have been identified, often using heat pumps. However, full electrification presents a challenge due to the variability in electricity availability and pricing.

To address this issue, we are exploring the following key questions:

- What are the options for achieving efficient, flexible, fully electrified industrial processes, given the variability in electricity availability, pricing, and future grid capacity?

- What are the technical challenges, and how do the different options compare?

- Which technologies or combinations of technologies are most attractive for different companies to implement?

- What is the optimal solution for both individual companies and the energy system as a whole?

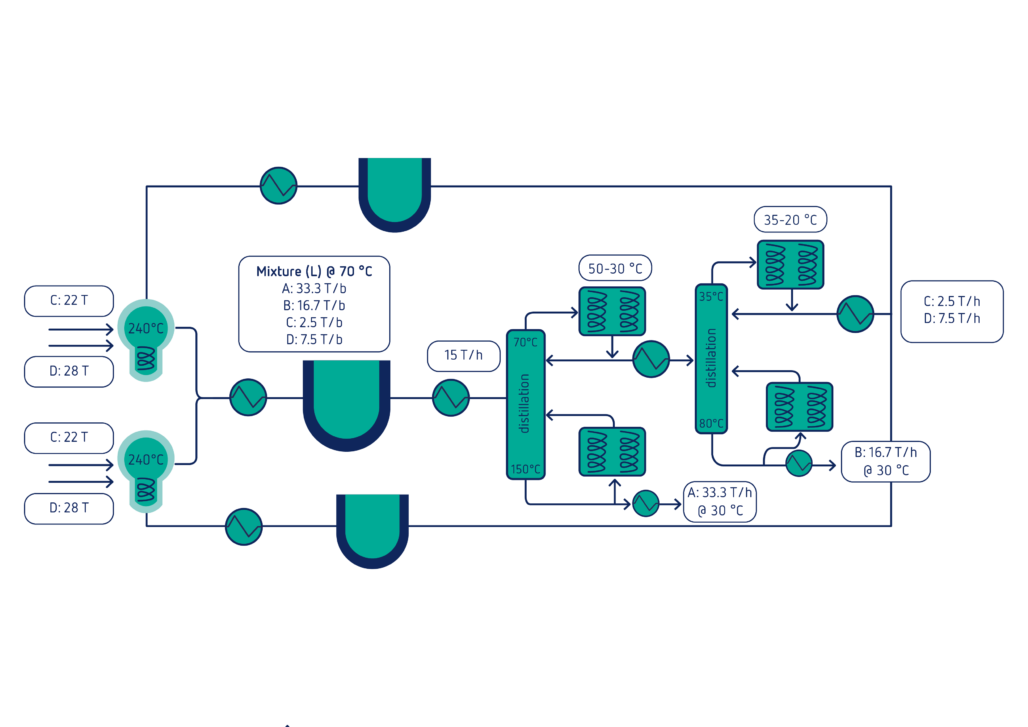

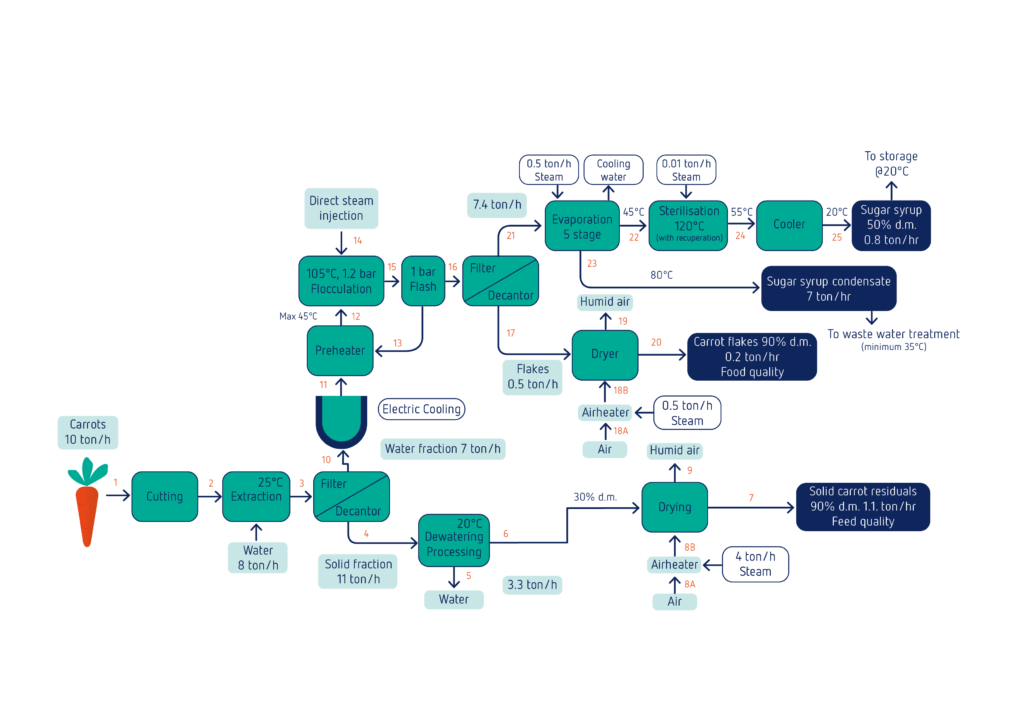

Two realistic virtual cases

To facilitate these discussions, we have developed two realistic virtual cases: one for an agro-food process and another for a chemical production process. These cases involve the most relevant heat-related unit operations, including all necessary technical details on the unit operations and process streams. They are designed to be inspirational and realistic examples for all industries. By setting up these cases virtually, anyone can share information and data on unit operations and possible smart solutions for electrification, even when these solutions are integral to the production process.

By working closely with industry, suppliers, and relevant experts, we approach the discussions from different angles. In this way we create mutual understanding on energy, process, and implementation aspects.

The challenge

We greatly value the input, insights, and involvement of all experts: other industries, consultants, technology suppliers, and students. Therefore, we invite you to take up our challenge and help us answer our research questions:

- What are the possible options for achieving an efficient, flexible, fully electrified process, considering variable electricity availability and pricing?

- What will the transition period look like (i.e. making optimal use of a variable electricity market while avoiding investment in redundant equipment)?

You can help us by developing multiple potential process designs using new technologies for renewable energy, electrification, and energy storage to solve the two virtual cases. We invite you to:

- Calculate electricity consumption per ton of product for each solution,

- define potential flexibility (minimum and maximum production, including electricity consumption per ton of product),

- and provide an indication of the business case for each solution.

Interested?

Are you up for this challenge? Please contact Agata van Oosten for more details about the challenge and detailed information on each of the cases.

Please visit our project page for more information on the Flexible Cases initiative.