Pyrolysis of different packaging plastics waste streams (DKR350) and films/foils (DKR310) was conducted at the pilot scale in a fluidized-bed reactor at 500 °C and 5 kg h−1 with the aim to investigate the impact of sorting, the variability of the feedstock, and process parameters on the yield and quality of feedstocks and product oils.

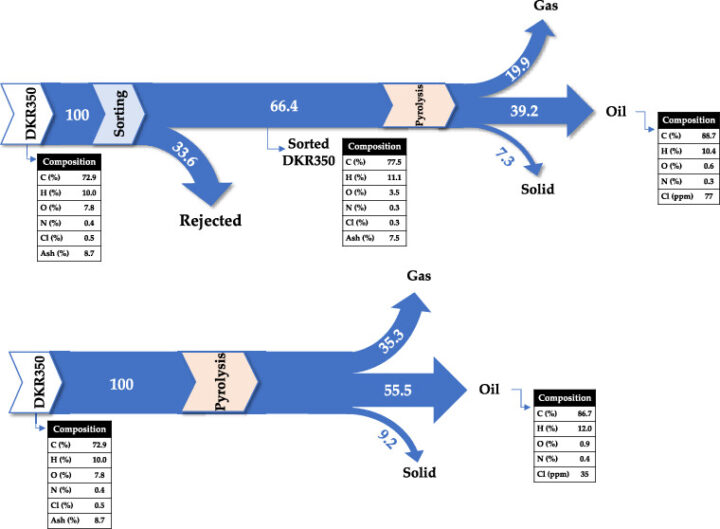

Sorting involved enriching the feedstock in polyolefins content, by mostly removing PET and clogged materials. The results indicated that sorting improved the quality of oil to a limited extent, compared to unsorted streams, as further processing will still be required before due to the presence of heteroatoms (e.g., O, Cl).

With the reactor and conditions used, the effect of the variable composition of this type of feedstock (e.g., depending on the location or season) is very limited, as the yield and quality of the condensable product remain similar. Both the effect of temperature and residence time is relevant and comparable, as an increase in either of these parameters favor cracking and aromatization reactions in the gas phase, leading to less condensable product and lower aliphatics/aromatics ratios in their composition.

Download your free copy

Our publications are free to access. Simply provide your first name and email address to download.