Pulsed compression is introduced for the conversion of methane, by pyrolysis, into ethylene. At the point of maximal compression temperatures of 900 to 1620 K were reached, while the initial and final temperature of the gas did not exceed 523 K.

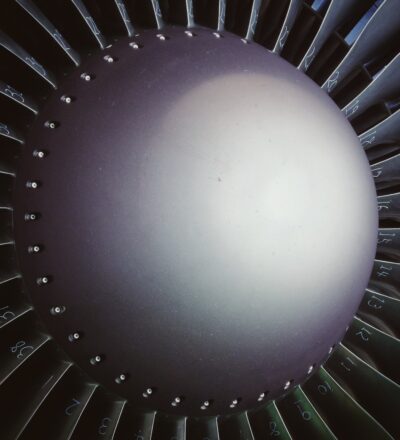

By the use of a free piston reactor concept pressures of up to 460 bar were measured with nitrogen as a diluting gas. From 1100 K onwards methane conversion was measured. By increasing the temperature, the mechanism of pyrolytic methane conversion, being subsequent production of ethane, ethylene, acetylene, benzene, and ultimately tar/soot, was clearly observed. Without hydrogen in the feed, the attainable operating window (C2-selectivity vs. methane conversion) observed was similar to other catalytic oxidative and non-oxidative coupling processes.

With hydrogen, in a first attempt to optimize the product yield, 24% C2-yield (62% ethylene selectivity, 93% C2- selectivity) at 26% conversion was reached without producing observable soot. It is worthwhile to explore pulsed compression further because it does not require a catalyst and therefore, does not deactivate over time and it operates at low reactor temperature.

Download your free copy

Our publications are free to access. Simply provide your first name and email address to download.