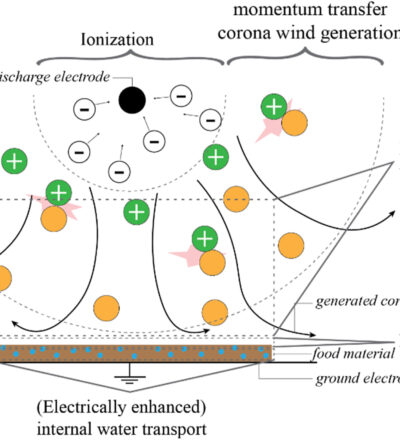

Electrohydrodynamic (EHD) drying offers an alternative to hot air drying thanks to its lower energy use and lower operating temperatures. EHD drying benefits from enhanced convection induced by the corona wind, but during the falling-rate period is constrained by internal moisture transport. It has recently been hypothesized that the internal transport can be enhanced since the product is subjected to an electric field.

This paper combines a theoretical analysis and experimental characterization to quantify the evolution of the electric potential across a thin layer during EHD drying of porous materials. Results reveal that during the constant-rate drying period, the electric potential remains low, confirming that drying is predominantly controlled by corona wind-driven convection. As drying progresses to the falling-rate period, the electric potential over the layer increases, which may facilitate electromigration. However, the material’s electric resistance simultaneously increases due to reduced moisture content, which may counteract this.

The quantification of the electric potential and material permittivity during EHD drying, advances our understanding of electrically driven mass transport, and will allow us to better model electrically-driven processes and drying, supporting the development of optimized EHD drying technologies.

Download your free copy

Our publications are free to access. Simply provide your first name and email address to download.