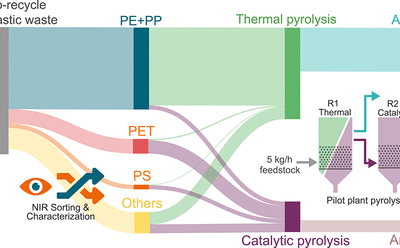

This study investigates the technological feasibility of recycling mixed plastic waste streams into chemical building blocks on a pilot scale. Postconsumer-separated DKR-350 mixed plastic waste was first separated into two fractions by using a two-step negative near-infrared (NIR) optical sorting process. The resulting two fractions (polyolefin-rich and polyolefin-poor) were subjected to thermal and ex situ catalytic pyrolysis, respectively. Both types of pyrolysis were performed in a fluidized bed pilot plant, continuously operated at feed rates of 5 kg h–1 and temperatures ranging from 460 to 550 °C. The polyolefin (PO)-rich fraction (∼81 wt % PE + PP) resulted in a maximum aliphatic-rich oil yield of 48 wt % and 26 wt % gas yield based on dry material intake. The PO-poor fraction, characterized by a lower PE/PP content (∼13 wt %) and high in PET and PS (43.5 and 14.4 wt %, respectively) normally unsuitable for efficient thermal pyrolysis, was processed through integrated cascading catalytic pyrolysis (ICCP) using a proprietary zeolite-based catalyst. This allowed for the successful transformation to 37 wt % aromatic-rich oil, with a total benzene, toluene, and xylenes (BTX) yield of 17 wt %, and 42 wt % gas. The high PET and PS content in the PO-poor fraction contributed to a significant increase in aromatic yields compared to the expected yield of a mixed plastic waste stream. This study thus demonstrates the potential to produce a full range of petrochemical building blocks, i.e., olefins and aromatics, from low-quality, hard-to-recycle plastic waste streams. Importantly, this work highlights that catalytic pyrolysis of the PO-poor residue stream, postsorting to yield PO-enriched streams, can effectively valorize this fraction, underscoring the technological viability of improved plastic recycling through targeted sorting and pyrolysis.

Download your free copy

Our publications are free to access. Simply provide your first name and email address to download.