This project investigates the behavior of silicon carbide membranes in pilot trials. These determine fouling, cleaning options, cleaning frequency and the consequences for the long term performance and economics.

Test long-term performance in pilot trials

The separation of oil from stable oil in water emulsions is a challenge, especially if low limits for oil in water are required as in the case of produced water (< 30 ppm dispersed oil). Many technologies have been studied, but proved to be technically or economically challenging (energy demand, need for additional materials, etc.).

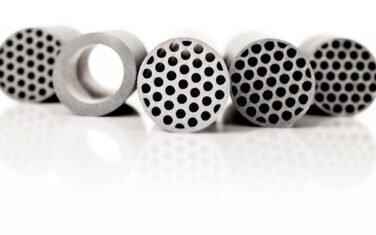

Ceramic membrane filtration proved to be an interesting option. Boundary condition is that the membranes can be operated and cleaned at rather extreme pH and temperature conditions. The existing zirconia or alumina membranes have a limited pH resistance and exhibit extensive fouling tendency under certain conditions. Silicon Carbide (SiC) does not have these limitations.

Previous projects (e.g. CombiClear) illustrated that the SiC membranes show a good performance for the treatment of oil in water emulsions. However, it still lacks the behavior of these membranes at duration tests and in particular cleaning possibilities of these membranes. In order to include these missing pieces of the puzzle, it will be studied in this project during a pilot trial, where fouling, cleaning options, cleaning frequency and the consequences for the long term performance and economics will be determined (TRL 7).

Extend applications of SiC membranes

Because SiC membranes are very robust, it is interesting to extend their applicability to other domains, such as food, dairy, pharmaceuticals, and chemistry. In this project the potential of the SiC membranes for several of these applications will be studied on a small scale (TRL 3-5) and will provide the performance of these membranes for these applications (flux, separation factor, etc.).

Because these other applications require partly different types of separation characteristics of the SiC membranes, the existing UF/MF range of SiC membranes will be extended to the nanofiltration (NF) range by the development of more dense coatings (TRL 3-4).

The project as a whole will deliver a good assessment of the feasibility of the SiC membranes, it will extend their feasibility to new applications and sectors, and derisk the technology with duration tests for challenging separation of stable oil in water emulsions. As a result, SiC membrane technology will be ready for large-scale deployment.

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-E&I with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Economic Affairs and Climate Policy.