What if we could recycle plastic film packaging into high-quality new materials – instead of burning it or shipping it abroad? The Cascade Plastic Film Recycling (CaRP) project is doing just that. With a smart cascade approach, this project transforms complex plastic packaging waste into a valuable resource, reducing CO₂ emissions and supporting circular industries.

In short:

- CaRP takes the theoretical framework of cascade recycling and turn it into realistic cascade recycling routes for plastic packaging film

- Focuses on practical, high-quality film-to-film recycling routes

- The project is built on real experimentation using actual waste streams (like LDPE 98/2 and DKR 310)

The problem

Plastic film is everywhere – from food packaging to shrink and stretch films in many logistic applications – but most of it isn’t properly recycled. Today, the majority of post-consumer film ends up in low-value products or is incinerated. The variety of materials and complex multilayer structures make it hard to recycle into something useful. What’s more, public data is lacking, and current sorting and recycling technologies struggle to deal with the volume and diversity of this waste stream. As a result, even though plastic film makes up a large share of our packaging waste, less than half is ever truly recycled.

About the project

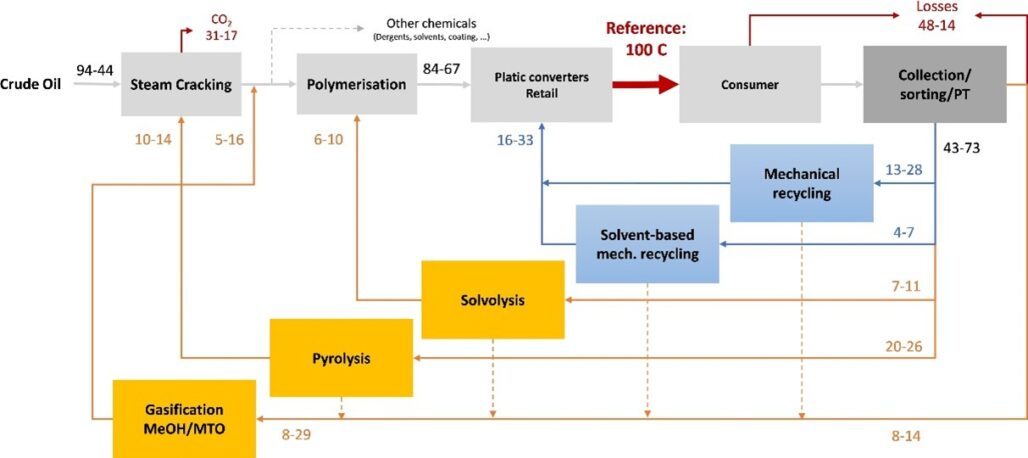

This project takes the concept of cascade recycling – the idea that different recycling routes can be matched to different types of plastic film – and makes it practical. By carefully selecting, sorting, and processing waste streams, the project designs recycling routes tailored to the material and its future use. The approach includes mechanical and chemical recycling methods, combining real-world trials with system analysis to find out what works best.

Expected Results

By the end of the project, Cascade Plastic Film Recycling will deliver:

- A full report on cascade recycling for plastic film

- Peer-reviewed paper(s) on cascade recycling of packaging film

- Techno-economic feasibility assessment

- A selection tool to match plastic film waste types to the best recycling route

- Physical outputs: clean flakes, pellets, pyrolysis oil, monomers, and new films – all from real-world recycling trials

The project is built on real experimentation using actual waste streams (like LDPE 98/2 and DKR 310). Every process is analyzed in detail for energy use, material balance, and output quality – delivering not just theory, but proven practice.

You might also be interested in

Acknowledgement & partners

This project is co-funded by TKI-Energy with the supplementary grant 'TKI- Toeslag' for Topconsortia for Knowledge and Innovation (TKI’s) of the Ministry of Climate Policy and Green Growth.