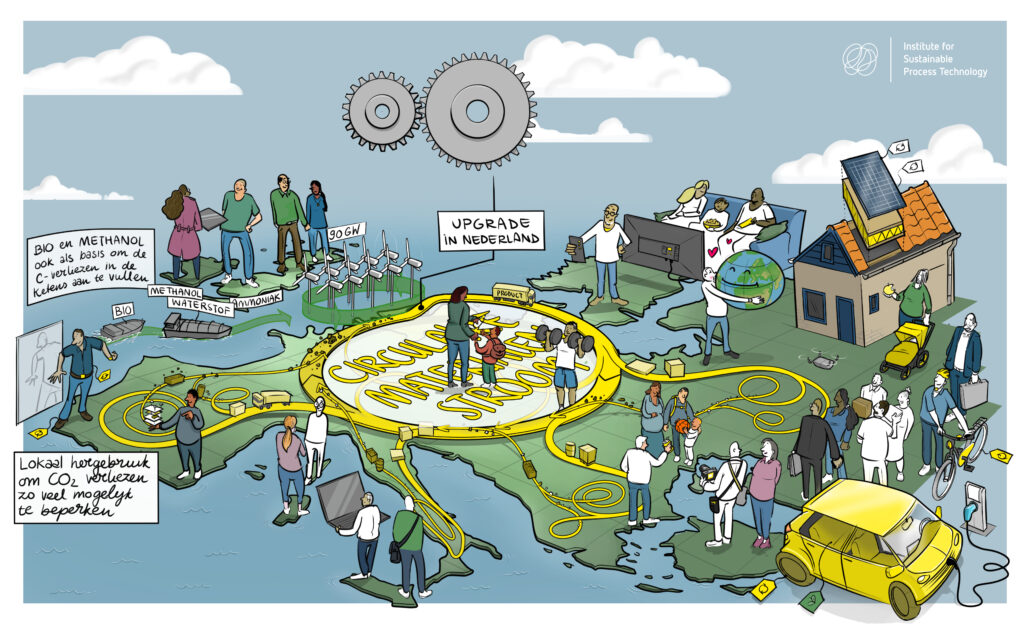

The Netherlands is priviliged because of our waterfront location and our entrepreneurial spirit. It will enable the Dutch industry to be a central player in the European landscape, unlocking great chances for industries focusing on recycling, reusing, and upgrading used materials.

As we look to the future, many of us aspire to live sustainably, yet we also desire clothing, a house to live in, travelling from A to B and nice things to make our lives pleasant and comfortable. Completely de-cluttering is hardly an option for most people. So, how can we introduce all these consumer goods to the European market (450 millon consumers) in a circular and carbon-neutral manner?

We believe that our privileged waterfront location and our entrepreneurial spirit could unlock this potential. The Netherlands has the opportunity to lay the groundwork for a circular industry, paving the way for a thriving economy, increased employment opportunities, and a hotbed of innovation.

The availability of relatively cheap green energy makes the Netherlands an attractive location for the energy-intensive circular industry

We have lots of cheap, green energy – an asset

To achieve a fully circular economy, we need a lot of energy. Simply because the sustainable production of consumer goods and the reuse of raw materials require lots of energy. And that is precisely where opportunities lie for the Netherlands. Because, thanks to our coastal location, the Netherlands has access to large amounts of sustainable and cheap energy.

- By 2030, we aim to produce about 21 gigawatts of wind energy at sea (this is 75% of our current electricity use)

- By 2040, there should be 50 gigawatts of wind power at sea

- By 2050, about 70 gigawatts

When we combine our own energy with offshore wind energy and hydrogen (coming to Dutch seaports from other regions of the world such as the Middle East, via energy carriers like ammonia and methanol) the circular processing of materials and waste streams can be further promoted.

We have an unique ecosystem to enable the circular feedstock hub of the future

The solution lays in the connection. Between companies, between sectors and between links in the chain. Directing parties such as ISPT are indispensable here, to facilitate those connections. Thanks to our ‘polder mentality’, we are used to talking to each other, finding solutions together and taking up the gauntlet together.

All this makes the Netherlands a very attractive location for the energy-intensive circular industry and Dutch process industry can take a leading position in sustainability.

The NTS Action Agenda Process Technology (January, 2026) reinforces why the Netherlands is so well positioned to lead the transition towards a circular, energy efficient industry. Our country hosts a concentrated cluster of energy-intensive industry, advanced chemical infrastructure, knowledge institutes, and a long tradition of public-private collaboration. The action agenda shows how this ecosystem can grow into a true circular feedstock hub for Northwest Europe.

This integrated ecosystem not only strengthens industrial competitiveness, but also unlocks societal benefits: securing critical materials, accelerating sustainable technologies, and building new industries that deliver lower emissions and advanced, future-proof products.

ISPT develops sustainability programs in consultation with the industry

At the Institute of Sustainable Process Technology (ISPT), we assist the industry and society in achieving circularity at multiple levels. We are independent, non-profit and based in the Netherlands.

The transition of the process industry is becoming increasingly complex. So complex, that companies can no longer do it alone. There is a need for solutions and innovations and that requires cooperation between multiple companies and in multiple links of the chain. Cross-sectoral collaboration is indispensable. Companies have to make an impact together. It’s a challenge, but also a great opportunity. The challenges we see can roughly be divided into 3 transitions:

That is where we play our part: creating a trust-based environment that connects the parties involved and facilitate their sharing of expertise and know-how in joint projects. This gets development off to a flying start and accelerates feasible, innovative and sustainable solutions that will lead to full circularity by 2050.

Let’s explore the 3 major transitions

Now, let’s dive deeper into the three major transitions: energy, raw materials and agro-food:

1. Energy transition

The use of sustainable electricity can significantly lower the CO2-footprint of the Dutch process industry. However, constructing the energy system of the future requires grid flexibility and a well-balanced energy mix of solar, wind, biomass, and green hydrogen.

2. Raw materials transition

Circularity is the cornerstone of a sustainable future. In a circular economy, resources are kept in use for as long as possible. Then, at the end of their service life, materials are recovered and regenerated. What is waste for one factory, might be a highly valuable resource for the other.

3. Agrifood transition

How to feed the world within the bounderies of the ecosystem? In order to do so, we need to redesign our food industry in a sustainable way, with process technology that helps us maximize nutritional values, has space for nature and builds a solid business case for our farmers.