Since the “War of the Currents” in the late 19th century, the electricity grid is based on Alternating Current (AC) technology. Water electrolysis, the electrochemical process of splitting water into hydrogen and oxygen, requires Direct Current (DC). The common way is to supply renewable electricity through an AC grid connection converting DC to AC and AC back to DC. Nowadays, HVDC transmission lines are increasingly developed for large offshore wind farms. It is therefore of interest to consider more optimised DC-DC connections for large scale green hydrogen plants. However, the required converters are not yet mature for this purpose and still need to be developed.

The Institute for Sustainable Process Technology (ISPT), in cooperation with Hitachi Energy and consortium partners Equinor, HyCC, Ørsted, Port of Rotterdam, and Yara, has completed a feasibility study to explore a (hybrid) electrical layout that incorporates DC and AC connections. The study focuses on developing optimised power conversion schemes for a gigawatt (GW)-scale water electrolysis plant.

Innovative converters for a large scale green hydrogen plant

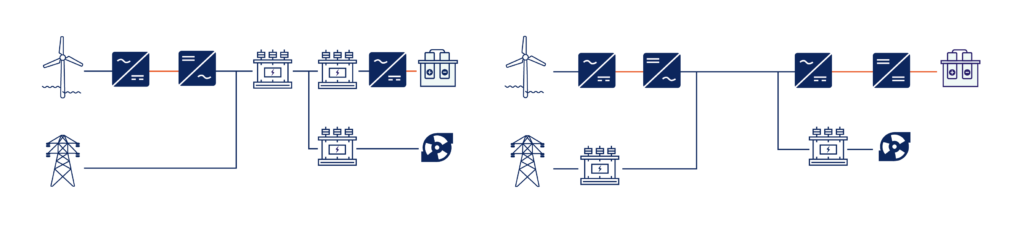

The objective is to prepare a conceptual design for a converter topology that enables the integration of this new electrical layout, highlighting both its benefits and limitations. Based on this design, a comparison has been made between a new electrical layout, which utilises novel converters, and a typical GW green hydrogen plant that employs transformers and rectifiers (see Figure 1). This comparison is carried out by detailed modelling using simulation software, evaluating the electrical performance of the entire plant – from the point of common coupling to the electrolysers. The analysis includes all transformers, switchgear, converters, cabling, busbars, and electricity consumers. The aim is to illustrate potential efficiency gains, power losses, harmonic emissions, grid requirements, and costs (CAPEX and OPEX).

A promising power converter scheme

The proposed layout has been selected as the most promising power converter scheme due to its relatively high maturity level, the suggested higher efficiency, the potential lowest complexity, costs, and footprint. This design utilises a power conversion topology that divides the medium voltage to a level suitable for the electrolyser module. Although other electrical layouts and power converter schemes were also identified, they were ultimately rejected in favour of this scheme.

Further development needed

The proposed innovative power converter will require further development in both hardware and software. It is recommended to further investigate the proposed innovative converters, optimizing the techno-economic size and feasibility, enhancing power quality, the galvanic isolation, and improving interfaces with the electrolysers.

Download the report to explore all the findings.