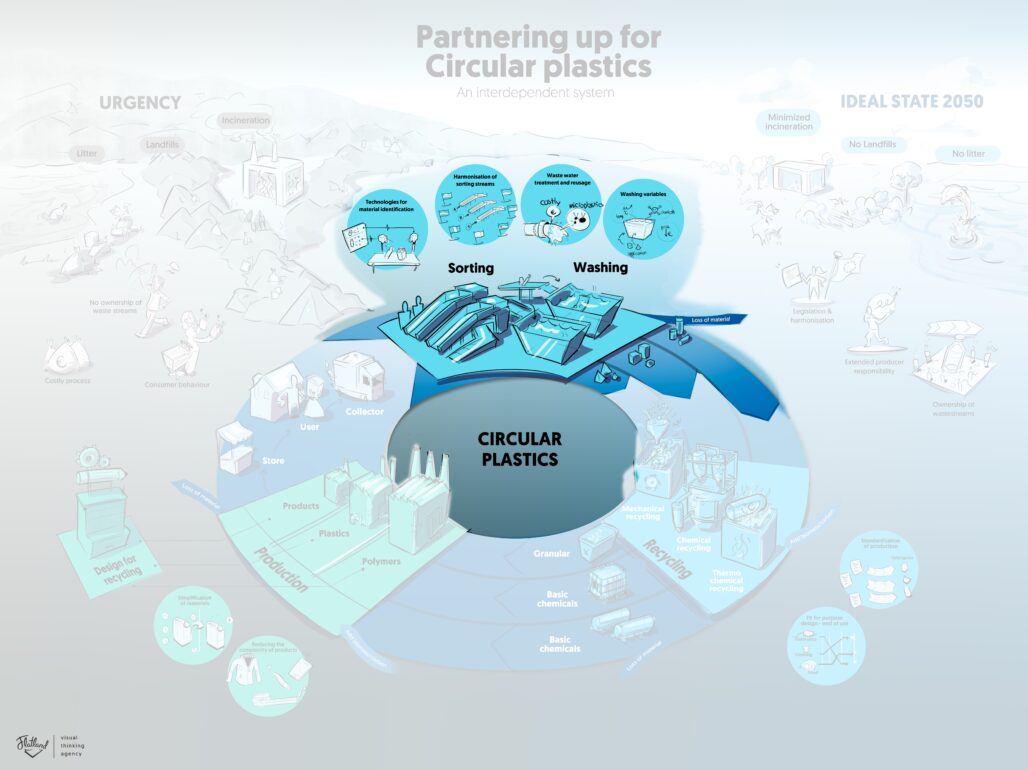

What techniques are needed for optimized sorting across value chains? How do we come up with flexible and modular process designs for various value chains, and forecaste the value of various recyclates?

New sorting and characterization technology needs to be developed for efficient sorting towards (future) feedstock streams for mechanical, chemical and thermochemical recycling will be defined by the newly designed plastic products.

Therefore, detailed guidelines regarding design-for-recycling are necessary. This gives input for collection and sorting models – including effective grinding and washing procedures – assessing multiple future scenarios. This is the only way to come up with realistic and cost efficient feedstock streams.

Realistic development and testing of technology is needed to:

- Validate the model

- Design realistic (and dedicated) sorting units

- Produce relevant feedstock streams for various reprocessing options

Priority of sorting techniques

- Assessment of needed characterization and sorting techniques for optimized sorting for the various value chains

- Implementing factors and data related to new sorting and washing techniques into the D4C model for various value

chains - Mechatronic development of sorting: flexible and modular process design with AI and machine learning for various value

chains - Development of an expert system that integrates analytical and context data to forecast recyclate value (for various value chains)

- Microplastics formation in sorting/washing will become an issue; assessment of issues and mitigation actions