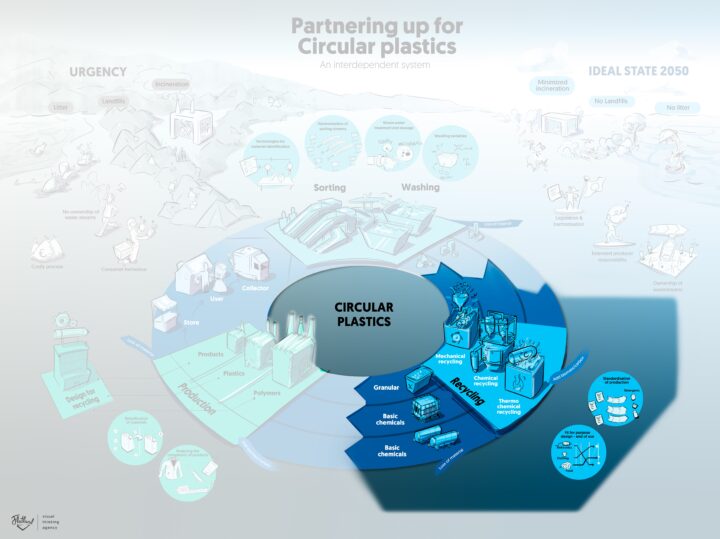

Recycling technologies are crucial to effectively manage plastic waste generated every year. Specifically, we need technologies that can efficiently and effectively process all the different types of plastics that are put on the market.

Dedicated feedstocks will be needed for the various reprocessing steps. Further sorting and/or pre-treatment using specific washing or dissolution strategies of the feedstocks may be necessary to prepare the right feedstock for reprocessing.

Next level extrusion, with integrated degassing and/or dissolution of additives and colourants needs to be further developed for mechanical recycling. Different types of solvolysis strategies will be needed, where effective recovery of solvent together with efficient separation of “other” materials should deliver clean streams of recycled material.

Pyrolysis in combination with thermal catalytics and advanced separation must deliver naphtha oil with high content of monomers for polymer catalysis.

Most urgent points of (thermo-)chemical recycling

- A multipurpose platform for process monitoring in chemical recycling technologies

- Efficient and effective separation techniques to deliver clean recyclates

- Optimize the efficiency of pre-treatment technologies

- Develop recycled material for multi-loop recycling

- Depolymerisation principles for composites to preserve fibres

Most urgent points of mechanical recycling

- A multipurpose platform for process monitoring in mechanical recycling technologies

- New and cheap in-line separation techniques for various types of mechanical recycling processes (film extrusion, injection

moulding, blow moulding, pipe/profile extrusion) - Deliver recycled material for multi-loop recycling

- Dissolution techniques for composites to preserve fibres