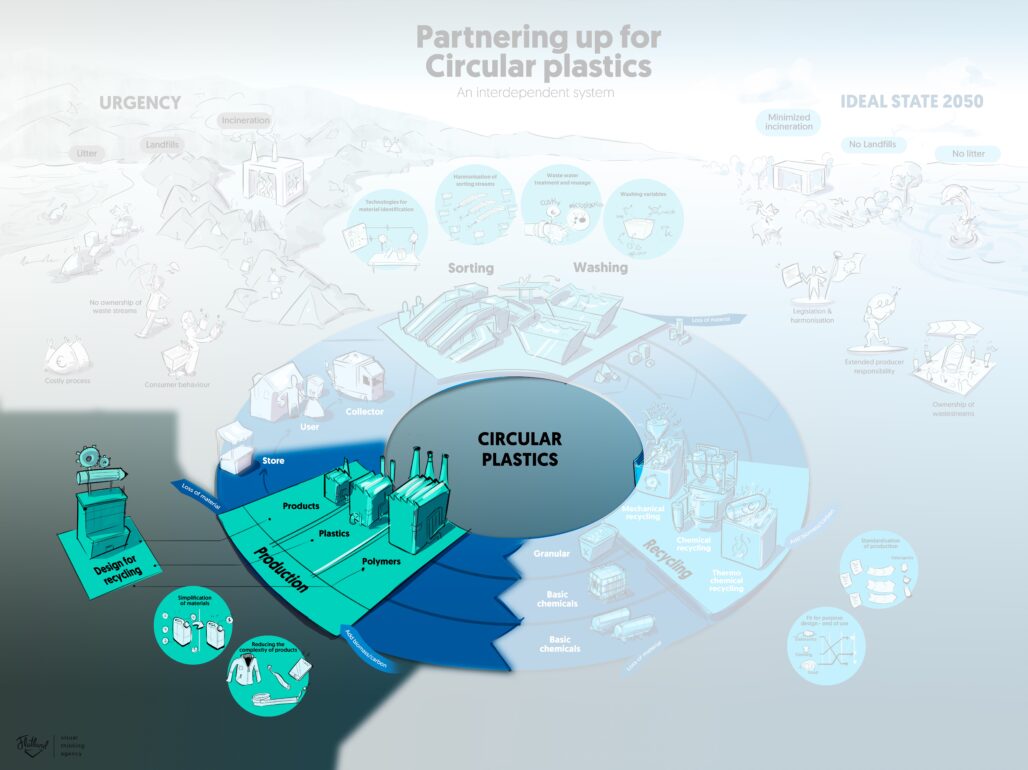

Incorporating design principles for recycling and circularity is key to improving the effectiveness and efficiency of plastic waste management.

Design for recycling as well as from recycling must deliver plastic products that can be recycled over and over. This means that the chemistry between polymer matrix and the additives/colourants/stabilizers etc. must change and that, after use, specific processes must be developed to release these additives from the plastic matrix so they can be recovered.

Therefor we need bright ideas from bright minds and dedicated collaboration.

Most urgent points of action

- Modelling and linking recyclate quality with design for various value chains:

- Packaging plastics

- Textile plastics

- Automotive

- Household appliance

- Rubber (tyres)

- Composites

- Industrial (B2B)

- Building/construction

- Define the main interfering substances for the various value chains and address ways to eliminate those through sorting

and /or processing - What are the needed design rules and processes that have to be implemented/ used to be compliant to (new) legislation

(for the various value chains and applications) - Modelling multi-layer mono-polymer process design and functionality for various value chains/applications

- Stability of products/applications when multiple recycling loops are implemented